Customized mechanical engineering industry support services for your business growth.

Customized mechanical engineering industry support services for your business growth.

Blog Article

Top Tips for Effective Electric System Troubleshooting

Troubleshooting electric systems requires a systematic method, based in an extensive understanding of electric concepts and security procedures. The nuances of efficient troubleshooting prolong past plain technical knowledge; understanding exactly how to document findings and prioritize security can dramatically affect outcomes.

Understand the Basics

Recognizing the basics of electric systems is vital for reliable troubleshooting, as a strong foundation enables professionals to diagnose and fix problems a lot more effectively. An extensive grasp of electric concepts, such as voltage, existing, resistance, and power, is important in determining the origin of problems. Voltage is the electrical possible difference that drives current through a circuit, while resistance opposes the flow of present, affecting the overall performance of the system.

Familiarity with circuit elements, consisting of resistors, capacitors, diodes, and switches, is likewise vital. Each component plays an unique role in circuit behavior and can impact performance when malfunctioning. Furthermore, recognizing series and identical circuit setups is important, as these plans affect the distribution of voltage and current within the system.

In addition, understanding of safety and security procedures is essential. Service technicians have to understand possible risks, such as shock and brief circuits, to apply safe troubleshooting practices. By mastering these foundational principles, technicians improve their capability to conduct effective diagnostics and repair work, inevitably resulting in boosted efficiency and reliability of electric systems. This fundamental understanding is the foundation of successful troubleshooting undertakings.

Gather Necessary Equipment

Effective troubleshooting of electric systems requires the ideal collection of devices to detect and fix problems accurately. A well-equipped professional can significantly improve performance and effectiveness in identifying problems. Necessary devices consist of a multimeter, which determines voltage, existing, and resistance, allowing for accurate evaluations of electrical parts. Clamp meters are additionally beneficial for measuring present without disconnecting the circuit, ensuring security and convenience.

Additionally, protected hand tools such as screwdrivers, pliers, and wire pole dancers are essential for securely manipulating electrical connections. It is also a good idea to have a circuit tester handy to verify the presence of voltage in electrical outlets and wires. For more complex systems, a thermal imaging cam can aid spot overheating elements, suggesting potential failings.

Adhere To a Methodical Method

Having gathered the ideal tools, the next action in troubleshooting electric systems is to adhere to an organized method. A methodical strategy makes sure that professionals can identify mistakes effectively and properly, lessening downtime and protecting against unneeded repair services.

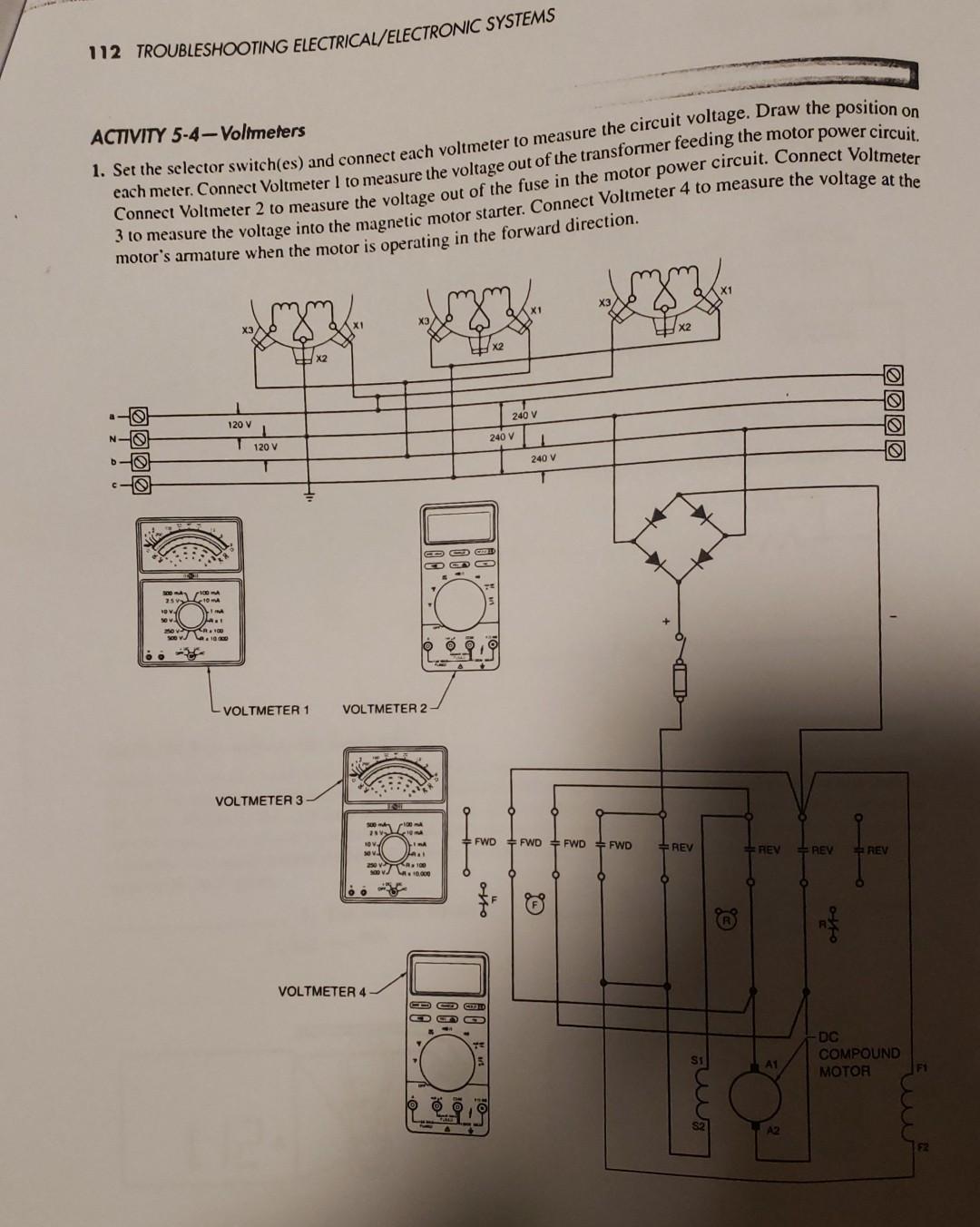

Begin by examining the system's schematic layouts and specifications. Understanding the style and operational parameters will certainly provide context for diagnosing issues. Next, separate the trouble location by utilizing a process of removal. This involves checking each component methodically, beginning from the source of power and working in the direction of the tons.

Utilize testing tools, such as multimeters and oscilloscopes, to gather unbiased data regarding voltage, existing, and resistance at different factors within the system. This empirical evidence will certainly direct your troubleshooting initiatives and help to validate or get rid of potential reasons of failing.

Furthermore, think about ecological elements that may affect the system's performance, such as temperature variations or moisture access. An extensive inspection of electrical wiring, connections, and elements will certainly make sure that all possibilities are represented.

Document Your Searchings For

Detailed documents is essential in the repairing process of electric systems. This technique not just help in recognizing the origin reason of the trouble yet likewise offers as a recommendation for future troubleshooting efforts.

In addition, maintaining a log of components changed or repair work performed is vital. This details sustains stock management and can try this help analyze the durability and integrity of details parts.

Eventually, the documentation procedure ought to be comprehensive yet succinct, enabling very easy retrieval and testimonial - electrical system troubleshooting. By prioritizing detailed documents, professionals can produce a valuable data base that not only help in present troubleshooting but additionally equips future upkeep efforts, therefore enhancing total system dependability

Prioritize Precaution

Acknowledging the fundamental dangers linked with electrical systems is crucial for guaranteeing safety and security during troubleshooting. Electrical shock, burns, and tools damage are just a few of the potential dangers that service technicians encounter. Prioritizing precaution is not only a lawful commitment yet likewise an ethical vital that safeguards both the technician and the surrounding atmosphere.

Prior to starting any troubleshooting task, specialists must wear ideal personal protective equipment (PPE), including insulated gloves, safety this website and security glasses, and flame-resistant apparel. Ensuring that the workplace is completely dry and without clutter can dramatically decrease the risk of mishaps. It is crucial to de-energize circuits prior to starting any type of work, confirming that they are not live via the use of a multimeter or voltage tester.

Developing clear communication protocols with team participants is additionally essential; this makes certain that every person is aware of potential threats and the standing of the electric system being worked on. Finally, having an emergency response plan in place can show invaluable in case of a case. By focusing on precaution, technicians can properly alleviate dangers and foster a more secure work environment.

Final Thought

Effective electric system fixing counts on a thorough understanding of essential principles and a systematic technique. By gathering crucial tools, sticking to methodical evaluation strategies, and carefully recording findings, the fixing process ends up read here being more effective and trustworthy. Prioritizing security measures makes sure the wellness of people involved and the stability of the electric system. Executing these approaches will improve the troubleshooting experience, causing quicker resolutions and improved operational efficiency in electrical systems.

Report this page